Polyurethane and Acrylic Soil Stabilization

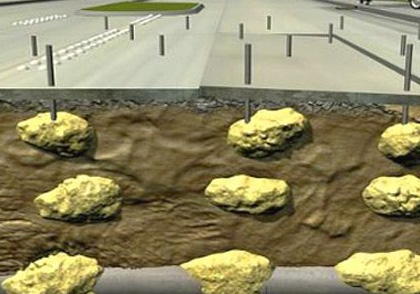

This extremely specialized field, chemical grouts are used to fill voids, stabilize soil, and create sub-grade grout barriers below roadways, in earthen dams, coastal seawalls, underground vaults and tunnel boring operations. A major advantage of chemical grouting is the ability to strengthen existing soils without the need for excavation or disruption of facility operations. As the popularity of trench less technology continues to grow, engineers and contractors are finding that they can use chemical grout to solve a multitude of problems caused by poor soil or excessive water conditions.

Arid Restoration Technologies uses products for both permeation and compaction grouting operations. Permeation grouting saturates the soil with an extremely low viscosity resin (Prime Flex 910 injected neat, AR 800 or Hydro Gel SX mixed with water). Compaction grouting results from injecting a two component, rapid set, highly expansive structural foam (Prime Flex 985 series) which fills voids and compacts soil by its expansive pressure.